TMT Rebars

TMT Rebars: The Foundation Of Construction Brilliance

Shreejii Bizz Corp provides a complete range of TMT (Thermo-Mechanically Treated) rebars engineered for strong, durable, and reliable structural reinforcement across all types of construction projects.

Our Fe 550D rebars offer high tensile strength, enhanced ductility, and excellent weldability, making them suitable for high-load applications such as bridges, towers, and large-scale infrastructure.

Our Fe 550 rebars deliver strong tensile performance and improved ductility, ideal for demanding structures and regions with higher seismic activity.

Our Fe 500D rebars provide superior bendability, high ductility, and improved corrosion resistance, ensuring long service life in varied environmental conditions.

Our Fe 500 rebars serve as a dependable reinforcement option for everyday concrete structures, offering consistent strength and durability.

Shreejii Bizz Corp TMT rebars are designed to meet stringent industry standards, ensuring reinforced structures that are built to last and perform reliably across diverse applications.

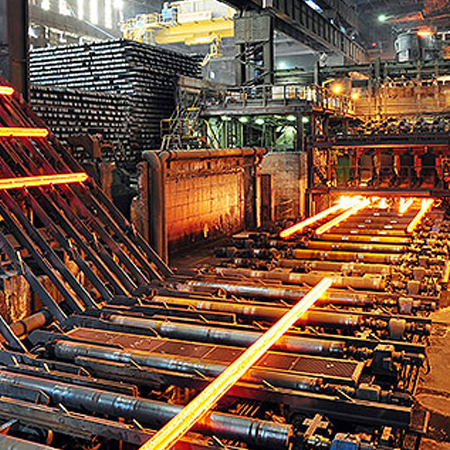

Ensuring Quality Excellence in Steel Production

At Shreejii Bizcorp Group, we understand that, as a discerning customer investing in your dream home, the quality of TMT bars that form its foundation is paramount. We empower our customers with the knowledge to make informed decisions, enabling them to choose materials that meet their exacting standards.

Renowned for our commitment to excellence, Shreejii Bizzcorp Group is recognised as an Integrated steel producer dedicated to maintaining the Highest Quality Standards across our range of products. Our in-house facilities span the entire production process, from Sponge Iron manufacturing and Iron ore crushing to Coal washery, Power generation, Furnaces, Automatic casting, Rolling mill for TMT bars, and Submerged Electric Arc Furnace for producing Silicone manganese & Ferro Silicon.

By overseeing every aspect of production internally, we ensure meticulous control over quality at every step. This vertical integration allows us to deliver TMT bars and steel products that not only meet industry norms but also exceed expectations, ensuring the durability and safety of your constructions.

Choose Shreejii Bizzcorp Group for your steel needs, where quality meets integrity and innovation meets reliability, ensuring your construction projects stand the test of time with strength and resilience.

| PARTICULARS | Fe-500 IS |

Fe-500 Shreejii |

Fe-500D IS |

Fe-500D Shreejii |

Fe-550 IS |

Fe-550 Shreejii |

Fe-550D IS |

Fe-550D Shreejii |

|---|---|---|---|---|---|---|---|---|

| %C | 0.30 Max | 0.18 - 0.25 | 0.25 | 0.17 - 0.23 | 0.30 Max | 0.18 - 0.25 | 0.25 | 0.17 - 0.23 |

| %S | 0.055 | 0.055 | 0.040 | 0.040 | 0.055 | 0.055 | 0.040 | 0.040 |

| %P | 0.055 | 0.055 | 0.040 | 0.040 | 0.055 | 0.055 | 0.040 | 0.040 |

| %S + %P (Max) | 0.105 | 0.105 | 0.075 | 0.075 | 0.100 | 0.100 | 0.075 | 0.075 |

| %C Equivalent (Max) | — | 0.50 | 0.40 | — | 0.61 | 0.58 | — | — |

| PARTICULARS | Fe-500 IS |

Fe-500 Shreejii |

Fe-500D IS |

Fe-500D Shreejii |

Fe-550 IS |

Fe-550 Shreejii |

Fe-550D IS |

Fe-550D Shreejii |

|---|---|---|---|---|---|---|---|---|

| Yield Stress N/mm² Min | 500 | 520 | 500 | 520 | 550 | 565 | 550 | 565 |

| Tensile Strength N/mm² Min | 545 | 575 | 565 | 585 | 585 | 615 | 600 | 625 |

| TS/YS. Ratio. Min | 1.08 | 1.10 | 1.10 | 1.12 | 1.06 | 1.09 | 1.08 | 1.10 |

| Elongation % Min | 12 | 17 | 16 | 18 | 10 | 15 | 14.5 | 16 |

| Mandrel Diameter Min for bend | 4D | 4D | 3D | 3D | 5D | 5D | 4D | 4D |

| % Total Elongation Min | — | 5 | 5.50 | — | 5 | 5.50 | — | — |